diy steam autoclave|steam autoclaves manufacturers : online sales 1000 Litre (250 Gallon) Autoclave: I made this large sterilizer for mushroom culture, but it could also be used for composite part layup. It was a fast build and there is some danger, so read and use precautions where indicated. Both dry heat and moist heat are used to sterilize objects. However, there is a huge difference between the two. Dry heat uses dry air of high temperature while moist heat sterilization uses a low temperature and a .

{plog:ftitle_list}

Steam sterilization, or autoclaving, stands as a key defense against microbial contamination. Utilizing steam under pressure, this method effectively sterilizes a wide array of medical tools and supplies.

1000 Litre (250 Gallon) Autoclave: I made this large sterilizer for mushroom culture, but it could also be used for composite part layup. It was a fast build and there is some danger, so read and use precautions where indicated.

This is my home made steam sterilizer build for mushroom growing. It uses a stainless honey collector and an 2500w element to heat water, then it pumps the s. Portable (table-top) steam sterilizers are used in outpatient, dental, and rural clinics. 840 These sterilizers are designed for small instruments, such as hypodermic syringes and needles and dental instruments. The ability of the sterilizer to reach physical parameters necessary to achieve sterilization should be monitored by mechanical . In this video we focus on my super cheap and effective barrel sterilizer. I explain the necessary parts in building your own barrel atmospheric sterilizer to.

I made my own homemade or DIY steam generator for sterilizing my mushroom substrate. The purpose of this steam boiler is to produce enough steam to heat my s.Custom Industrial Steam Autoclaves for Sale. Each Priorclave steam sterilizer is built to order, which helps ensure the best possible match to your tasks, facilities, and requirements. We back our quality construction and reliable design with the best support program of any autoclave or steam sterilizer supplier: a 36-month limited parts and .Let’s just review what happens in the autoclave. We open the door, and place the load [1] [2] inside the autoclave chamber. The load refers to whatever we wish to sterilize, i.e., surgical instruments, as well as laboratory essentials like solids, liquids, or hollows. Once we close the door and set the autoclave to the appropriate cycle, water begins to enter the chamber and . Attaching the fittings on a home made single drum sterilizer designed by me. All the parts needed to build your own DIY single drum sterilizer can be purcha.

Check out this K-Type Thermocouple https://www.amazon.com/dp/B0043964P4?tag=what044-20Support What The Fungus Here: https://www.patreon.com/whatthefungusAppa.Barrel steam sterilizers are ideal for this and popular with small mushroom farmers who don’t have the funds for an autoclave. As they operate without pressure, they’re less expensive, and it’s possible for growers to build their own DIY barrel steam sterilizer.Steam sterilizers (also referred to as autoclaves) are an essential part of the decontamination and sterilization process performed by sterile processing departments (SPD) in healthcare facilities. STERIS offers one of the broadest range of steam sterilizers and has a solution available to maximize department productivity and optimize workflow.

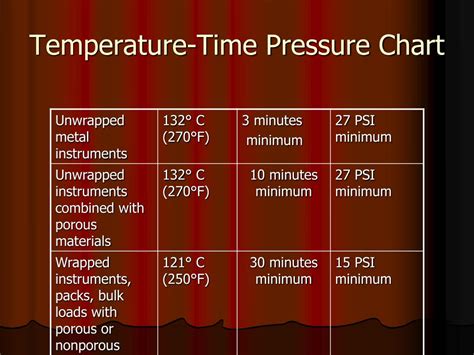

When you try to use steam at atmospheric pressure, steam is prevented from reaching higher temperatures. However, as you increase the pressure in a Mushroom Autoclave, you can increase both the temperature and the pressure together at the same time. Your Mushroom Autoclave can quickly reach 15PSI and 121°C. The upper pipe takes steam from the exhaust on the sterilizer barrel, to utilize 'waste' steam to heat the slab in the growing room. The lower fitting can take steam directly from the boiler to provide heat for the growing rooms when the sterilizer is not in operation. Gate valves feeding a copper 'T' determine which direction the steam flows. Autoclaves are widely used in the pharmaceutical industry for sterilization of equipment, materials, and products. In this video, we will explain the princip.Grain needs to be sterilized before it's incoluated with mushroom mycelium.www.southwestmushrooms.comwww.michaelcrowemycology.com Watch extended episodes: h.

Shipped From Abroad Horizontal Pressure Steam Autoclave uses saturated steam as the sterilization medium,exhausts the cold air by gravity. So that the saturated steam fully penetrates the surface of the items. By utilizing high-temperature saturated steam under high pressure, it effectively kills all microorganisms and their spores, providing reliable sterilization results. It is .

Steam sterilizers — also known as autoclaves — are an essential piece of equipment in any laboratory, research, or healthcare setting, ensuring sterility for important equipment and instruments. Autoclaves are available in a wide array of designs, each tailored for specific applications, ranging from small-scale laboratory sterilization to .Purpose-built laboratory autoclaves flood a sealed chamber with high-pressure steam under constant monitoring. These programmable units make most lab sterilization tasks extremely easy. For common tasks (like sterilizing . A bit of a long video but I hope it can help people looking to build their own sterilisers! I'll be selling the DIY kits in my store soon. Check out the blog.

what is autoclave sterilization

The allows for the steam to penetrate and be released from the packs properly. Also, allow larger packs that might block the steam to be placed on the bottom shelf of the autoclave. . then start. The Autoclave runs on four cycles, the heat up cycle, sterilization cycle, depressurization cycle, and the drying cycle and the time it will take .Yamato steam sterilizers are suitable for lab applications in many industries such as pharmaceutical, life science, food safety, and water based lubricant and coolant industries. For these research laboratories, Yamato autoclaves can disinfect liquid samples as well as solid apparatus. With liquid samples, effective sterilization depends on .

Industrial AutoclavesManufacturer Safe, user friendly, and efficient; with one of the quickest deliveries of large industrial autoclaves! Overview – Large Industrial Autoclaves Didion Autoclave is a designer and manufacturer of ASME certified industrial large autoclaves in Bellevue, Ohio, USA. We also perform repairs and re-builds. In addition, our company can help with the install .

What you don’t need to worry about regarding Celiton’s models when making your choice is the quality of the steam sterilization: regardless of size, all of your steam sterilizers provide the same efficiency, so you don’t need to worry about a smaller autoclave not being able to keep up with the quality of the bigger models. By harnessing the power of steam, pressure, and time, autoclaves can effectively eliminate microorganisms and spores, ensuring a safe and sterile environment. Adhering to proper procedures, understanding compatible and incompatible materials, and ensuring regular autoclave validation are essential for the successful and safe use of autoclaves. .The effectiveness of the moist heat is one of the basic principles behind the autoclave, which uses steam under pressure to disinfect items. Drs. Pasteur and Chamberland expanded on his work in a way that led to the invention of the autoclave. Combining the disinfecting power of steam with high atmospheric pressure resulted in a system that .

This autoclave provides high-performance, high-capacity steam sterilization for a broad mix of instrument sets and medical devices. How Does the AMSCO ® Evolution Medium Steam Sterilizer Work? The AMSCO Evolution Medium Steam Sterilizer unique chamber shape promotes even pressure and heat distribution within the medium autoclave. The steam pressure autoclave can also be used in busy group practices, emergency clinics, nursing homes, veterinary clinics, and small hospitals. Class B Autoclaves Pros: Versatility: Can sterilize solid instruments, porous .How does an autoclave work? Irrespective of whether it is a small tabletop autoclave unit or an industrial-sized bulk autoclave unit, all steam autoclaves operate using principles similar to those of a kitchen pressure cooker- that is, the chamber is sealed and all air within is replaced by steam. Three factors are critical to ensure successful steam sterilization in an autoclave - time .

Step by step assembly of a Bubbas Barrels mushroom drum bulk sterilizer. Shown is a 110 gallon but they are available in 55,85,130 and 150 gallon. This steri.

steam sterilization temperature chart

lab 23 12 pipette 5 ml of cola into beaker

lab advantage pipette tips

steam autoclaves manufacturers

LISA 517/522 Sterilizers require servicing every 4000 cycles or 5 years by authorized service technicians. The service includes replace- ment of consumables and other important internal components, a safety and system .

diy steam autoclave|steam autoclaves manufacturers